Processing the cut of the sleeve of a men's shirt with a placket. Processing of sleeves in a men's shirt according to Italian technology: sleeve slit. Long placket at sleeve slit

The bottom of the long sleeve in men's shirts, as a rule, is made with a stitched cuff. 1-2 one-sided folds are laid along the bottom of the sleeve and a fastener with stitched straps is processed (Fig. 1).

The sleeve is usually used one-sutural. The processing of the fastener of the sleeve is carried out before the sewing of the longitudinal sections of the sleeve.

One or two straight loops can be overcast on the top strap of the fastener, and one or two buttons can be sewn onto the bottom strap. This is not only an element of decor - the fastener with loops and buttons prevents the opening of the fastener of the sleeve during the operation of the shirt. The clasp can be hidden (Fig. 2).

The fastener of the shirt sleeve can be made decorative (ill. 3): the upper bar is made of two materials (main and finishing), and the lower bar is made of a finishing material.

Stitching the sleeve into the armhole of the shirt

In all men's shirts, the sleeve is sewn into the open armhole. After that, the side sections of the product and the longitudinal (lower) sections of the sleeves are ground off, then the cuffs are sewn.

To sew a sleeve into an armhole, one of three types of seams can be used: a linen double seam (Fig. 4), a linen sewing seam (Fig. 5 and 6) or a stitched seam.

The connection of the longitudinal sections of the sleeve and the side sections of the shirt is carried out with the same seam as the stitching of the sleeves into the armholes (Fig. 4-6). When sewing the side cuts, it is important to align the seams of the armhole.

Sleeve cuff finishing

The most popular are cuffs with loop and button closures (ill. 7-9). They can be with a right lower corner (Fig. 7), with a rounded corner (Fig. and with a truncated corner (Fig. 9). A different number of loops / buttons is also possible: one, two vertical and two horizontal. Two horizontal located loops / buttons allow you to adjust the length of the cuff.

In addition to cuffs with a fastener for loops and buttons in shirts, cuffs with a fastener for cufflinks are processed (Fig. 12).

The stitched cuff can be with a lapel (French cuff) - ill.11.

If the cuff has right angles (fig. 7), it can be cut out in one piece with cuff lining along the line of the lower edge - i.e. be made up of one piece. In other cases, the cuff and cuff lining are cut out separately. Cuff liners can be cut from adhesive or non-adhesive gasket material, the choice depends on the properties of the material of the upper. It is possible to duplicate the cuff and cuff lining or only one of them. As a rule, the cuff is duplicated so that the seam allowances do not lie.

In the manufacture of men's shirts, semi-automatic equipment is widely used in production. This is facilitated by the unification of the components of the product. Consider two options for processing the cuff and connecting it with the sleeve.

This is a variant of the production processing of the bottom of the sleeve with a cuff using special equipment (Fig. 10).

Line 1 - stitch (seam width 0.7 cm) the upper cut of the upper cuff (1 cm).

Line 2 - Overstitch the side and bottom edges of the cuff with the cuff lining (seam width 0.7 cm). Trim the seam allowances of turning to a width of 0.4 cm, cut off the allowances in the corners. Turn cuff right side out. Iron, straightening the piping 0.1 cm from the cuff, or without piping (depending on model features).

Line 3 - outline, overcast and cut a straight loop on the cuff.

Line 4 - connect the cuff and the cuff lining to the sleeve in one step with a seam 0.1 cm wide.

Line 5 - Lay the finishing line along the sides and bottom of the cuff with a seam 0.6 cm wide.

Iron the knot of the product. Mark the position of the button and sew it to the cuff.

Method 2

On ill. 11 shows how to process a French cuff with a lapel on a lockstitch machine. In this case, both parts of the cuff are duplicated.

Iron the top allowance (1 cm) of the cuff to the wrong side. Overstitch (line 1 in Fig. 11) the side and bottom edges of the cuff with a cuff lining with a seam 0.7 cm wide. Turn cuff right side out and iron without piping.

Sew the cuff lining to the cut of the bottom of the sleeve with a seam 1 cm wide (line 2 in Fig. 11), iron the seam onto the cuff lining. Sew the pressed upper edge of the cuff onto the seam of the cuff lining, sewing a stitch at a distance of 0.1 cm (line 3 in Fig. 11). Iron.

Lay the finishing stitch along the sides and bottom of the cuff with a seam 0.7 cm wide (line 4 in Fig. 11). Iron.

Bend the cuff, mark the position of 4 straight loops (on the cuff and lapel on both sides). Sew over and cut through the straight loops of the cuff. Insert cufflinks into loops.

A similar version of the French cuff with a lapel is shown in Fig. 12.

The cuff, just like the fastener of the sleeve, can be trimmed, for example, its edges can be processed with a piping seam (Fig. 13).

Shirt with rolled sleeves

Recently, casual style shirts are fashionable to wear with rolled sleeves. It is very easy to do this. It is enough to sew a button on the sleeve at a distance of about 25 cm from the highest point of the collar of the sleeve. The button should be at the same level as the cuff buttonhole. On the wrong side of the sleeve under the button, it is recommended to sew an amplifier - a piece of fabric from the top.

The process of wrapping the sleeve is shown in illustrations 14-16.

ill. 14 - fasten the cuff to the button of the sleeve, bending the sleeve with the wrong side out.

ill. 15 - then turn the lower part of the sleeve twice, overlapping the cuff.

ill. 16 is the finished result. Comfortable and fashionable.

Processing the cut of the bottom of a men's shirt

There are several ways to process a cut of the bottom of a men's shirt:

■ overcast the bottom section on an overlock, bend it to the width of the bottom hem allowance (0.5-0.7 cm) and stitch with a seam 0.2-0.5 cm wide (ill. 17);

■ Finish the bottom section with a hem seam with a closed section (Fig. 18).

Today, another characteristic element of the shirt has appeared - an amplifier (insert) along the bottom of the side seams (ill. 19). The amplifier can be embossed with a company logo. But this is not only a marketing ploy, but also a functional element. The reinforcement protects the lower section of the side seam from tearing.

The side seam reinforcement can be of various shapes (Fig. 19, 21, 24 and 27). Ways of attaching it to the product are also different. Let's consider four options.

Option 1

Consider the option of strengthening the lower section of the side seam of a classic men's shirt with an amplifier in the form of a triangle (Fig. 19).

Cut out the detail of the amplifier in the form of a rhombus with allowances along the contour of 0.5 cm. Iron the detail in half. Iron the seam allowances along the entire contour of the part to the wrong side.

The amplifier is tuned to the product after processing the side sections and the bottom cut (Fig. 20). With a detail of the amplifier, go around the edge of the bottom of the shirt so that the side seam of the shirt is in the middle of the amplifier, and stitch, capturing all the layers with a line. Iron.

Option 2

The second option (ill. 21 and 22) is more suitable for casual and sports men's shirts. The amplifier in this case is cut in the form of a rectangle with seam allowances of 0.5 cm along the contour. Iron the seam allowances to the wrong side of the piece. Iron the outer part of the amplifier (1 cm) to its wrong side.

Finish the side seams and the bottom of the shirt (line 1 in Fig. 23). Lay the inner wide part of the reinforcement on the wrong side of the shirt so that the side seam of the shirt is located in the middle of the amplifier. Stitch the inside of the reinforcement on three sides with a seam 0.1 cm wide (line 2 in Fig. 23). Bend the outer part of the amplifier to the front side of the shirt and stitch it on three sides with a seam 0.1 cm wide (line 3 in Fig. 23). Iron.

Option 3

This method of strengthening the bottom of the side seams (ill. 24 and 25) is typical for all types of men's shirts - classic, casual, sports.

The detail of the amplifier is cut out in the form of a rhombus (ill. 26). The size of the reinforcement should correspond to the open area between the curly lines of the bottom of the front and back of the shirt, plus allowances for seams (at least 1.5 cm for each cut).

Visually divide the rhombus vertically in half, iron the allowances of one half of the rhombus 0.5 cm inward. Sew the sections of the other half with a seam 0.5 cm wide.

The ironed allowances of the diamond should not be bent when turning. Turn the amplifier right side out. Iron. Stitch the ironed edges of the reinforcement with a seam 0.2 cm wide (Fig. 26).

Process the side sections of the shirt and the bottom section. Put the prepared reinforcement on the wrong side of the shirt and stitch, laying the lines along the lines of sewing the hem of the shirt bottom (ill. 24, 25). On the front side of the shirt, place a bartack at the end of the side seam. Iron.

Option 4

This option (ill. 27 and 28) is typical for everyday and sports men's shirts.

The amplifier is cut out in the form of a pentagon with seam allowances of 0.5 cm along the contour, except for the lower cut. The allowance for the lower cut of the amplifier is designed to be the same width as the allowance for the hem of the bottom of the shirt. Iron the allowances of 0.5 cm along the entire contour of the part, with the exception of the allowance along the lower cut.

Process the side sections of the shirt. Lay the reinforcement on the wrong side of the shirt so that the side seam of the shirt is in the middle of the reinforcement. Sew it on all sides, except for the bottom cut, with a seam 0.1 cm wide (line 1 in Fig. 29).

Finish the bottom of the shirt with a hem seam with a closed cut along with the reinforcement (line 2 in Fig. 29). Iron.

There are many ways making a cut or slots on the sleeve. If it is very narrow, you need such an incision so that the hand can pass through. However, the slit and vent can be a decoration or a style element - for example, on the sleeve of a classic jacket. A sleeve with a wide cuff always has a slit. But before making a cut or slot, you need to check the length of the sleeve.

Clean cut cut

This incision is made on sleeves with cuffs in cases where the edges of the incision do not overlap and the cuff has an allowance for the fastener (1). To process the incision, you will need a strip of fabric (= facing), cut along the equity thread, 4 cm wide and 4 cm longer than the finished incision. Lay a running thread on the sleeve along the line marked CUT. Pin the piping to the sleeve over the cut mark right side to the right side (2). From the wrong side of the sleeve, lay along the line on both sides of the marking close to it, lay 2-3 transverse stitches at the upper end.

Make a cut between the stitches, at the end of the cut into the corners make oblique notches (3). Sweep the facing on the wrong side. Iron the edges of the cut, stitch to the edge (4). Sew over the edges of the facing with a zigzag stitch or, tucking it, pin it and stitch it to the edge.

INTERESTING OPTION

The facing simultaneously acts as a plank. To do this, stitch the facing with the front side to the wrong side of the sleeve, make a cut, unscrew the facing to the front side, fold and stitch (5).

Obtachny cut

This type of incision is most often performed on the sleeves of blouses and shirts. The edges of the cuff coincide with the edges of the incision (6).

To process the cut, you will need a strip of fabric 2 times longer than the cut and 4 times wider than the finished facing.

For soft, thin fabrics, cut the strip in the direction of the grain thread, and for dense, thick fabrics, such as poplin or flannel, cut the strip along the bias.

Cut the sleeve along the cut line. Lay the edges of the cut in a straight line and stitch to the facing right side to the right side close to the cut. In this case, at the end of the cut, marked with an arrow, lay a line almost at the cut (7). Iron the seam allowances on the facing. Iron the other longitudinal section of the facing so that the distance from the fold to the stitching seam is twice the width of the finished facing (8). Fold the seam in half wrong side inside and pin to the sewing seam (9). Sew the piping by hand or sew on the right side of the sleeve close to the seam, while grabbing the inner half of the piping. At the top end of the slit, stitch the piping diagonally, like a small tuck. At the front edge of the cut - this is the edge located further from the side cut of the sleeve - turn the facing to the wrong side, pin (10). At the rear edge of the cut, the facing acts as an allowance for the fastener.

Classic slit sleeve men's shirt

In such slots, the edges of the cuff coincide with the edges of the slots (11). Its peculiarity is that the slots of the right and left sleeves are symmetrical. For this slot, the basic rule applies: the edge of the slot, which lies closer to the seam of the sleeve, serves as an allowance for the fastener.

Cut out a strip of fabric for facing in the direction of the shared thread: twice as wide as the finished facing, plus allowances for the seams and 5 cm longer than the marked line of the slots.

Cut the sleeve along the marked line of the slots, for the allowance for the fastener, make oblique notches at the end of the slots to a depth of 0.5 cm. Fold the facing along the right side inward. Stitch the upper sections to the desired width of the facing, then sew the longitudinal sections with a single line for a length of 3 cm. Pin at the end of the seam.

Notch the seam allowance close to the last stitch, cut the seam allowance close to stitch (13). Turn the trim inside out and iron.

Sew the fold to the edge from the bottom up, not reaching 3 cm to the end of the facing. Sew the outer half of the facing close to the front raw edge of the slots right side to the right side (14). Notch the seam allowance of the sleeve at the end of the seam close to the last stitch. Iron the seam allowances on the facing. Turn the inner half of the facing over and baste it to the stitching seam (15). On the right side of the sleeve, stitch the piping along the joining seam close to the seam, while topstitching the inner half of the piping. Next, continuing the line, sew the upper end of the facing to the sleeve. Then, at the end of the slots, stitch the piping crosswise (16).

IMPORTANT: the illustrations show the slot of the right sleeve. On the left sleeve, make a slot in a mirror image.

Fake slot, or slot made with a steering wheel

This is the easiest and fastest way to make splines (17). It is performed on short sleeves and 3/4 length sleeves, as well as on sleeves with figured cuffs.

The slot is processed without a cut. Cut the allowance along the lower cut of the sleeve twice in the area of the slots close to the marked seam line (18). The distance between notches is approx. 4-5 cm. Iron the allowance between the notches on the wrong side, tuck and stitch to the edge (19) or sew by hand. When sewing off the cuff, grab the narrow edges of the slot allowances.

Sleeve slit

When the lower edge of a long sleeve with a longitudinal tuck is not wide enough for the arm to pass through, then an incision is made in the tuck. This slit fastens with a zipper or buttons with air loops.

ZIP PIECE

Mark the beginning of the cut on the tuck with a cross mark. Fold the sleeve with the right side inward so that the lines of the tuck line up. Baste the tuck, while also basting the edges of the cut like a seam.

Stitch the tuck from the cross mark to the top. Bartack at the beginning and end of the seam. Notch the tuck 1 cm above the mark almost to the line and cut in the middle from the bottom to the notch (1). Iron the seam allowances, iron the tuck flat. Trim the seam allowances to a width of approx. 1.5-2 cm (2), overcast.

Remove the running thread from the incision. Cover the edges of the cut. Sew the zipper under the edges of the cut from the marked line of the bottom edge.

Sew the ends of the zip fasteners to the tuck. Fold along the bottom of the sleeve. Sew the allowance to the straps of the zipper (3).

AIR LOOP FASTENING

Sew the loops to the front edge of the slit - the one that is further from the sleeve seam. For the front edge of the incision, you will need to cut out a facing (strip of fabric) in the direction of the lobar thread with a width of approx. 3 cm and 2 cm longer than the cut. For air loops, cut a strip of fabric along the bias. How to perform air loops, you can read in a separate article. In addition, you will also need two strips of non-woven interlining, cut along the bias, approx. 2 cm and a length equal to the length of the incision.

On the right and left sleeves is performed symmetrically.

Mark the length of the cut on the tuck. Cut the tuck from the bottom to the cut mark to a depth of 0.5 cm from the front line of the tuck. For the closure allowance, draw another line from the end of the cut to the bottom of the sleeve at the same distance to the other line of the tuck. Make a cut along this line. At the top to the middle of the allowance for the fastener, make a transverse notch. From the right side of the sleeve, iron the interlining strips along the front edge of the slit over the marked seam line, for a closure allowance along the tuck line (4).

Baste chain loops to the front edge of the opening, right side to the right side.

Pin the facing over the loops right side to the right side, stitch from the cut mark (5). Turn the top edge of the facing down, pin (6). Stitch the tuck from the cut mark. Bartack (7) at the beginning and end of the seam. Unscrew the facing to the wrong side. Baste the edge of the cut.

For the closure allowance, fold the back edge of the slit to the wrong side at a distance of 1 cm from the intended tuck line. Iron the edges, iron the tuck to the front cut of the sleeve (8).

Sew the seam of the sleeve. Remove running threads from the incision. Hem the bottom of the sleeve.

Peel off the slit and sew a tuck at the top end of the slit. Sew the buttons to the closure allowance.

Double seam sleeve

This vent is made on the sleeves of blazers, jackets and suit jackets. There are two options for slots in a two-seam sleeve: classic, in which a real slot is made, and fake, in which the slot is only a decorative detail.

CLASSIC SLEEVE SLEEVE

Open vent at the bottom of the sleeve. The upper part of the sleeve is cut together with the facing of the slots, the lower part of the sleeve is cut with an allowance for the slot with the facing.

Sew the front seam of the sleeve first. Iron the seam allowances. Iron the interlining to the lower cut of the sleeve (hem) and to the facings.

Baste the elbow sections of the sleeve, at the same time sweep the slot. Sew a seam from the top to the slot mark. Bartack at the beginning and end of the seam. Leave the slot sour cream (1). Notch the seam allowance of the bottom of the sleeve into the corner obliquely close to the stitching line (2). Iron the seam allowances from above to the notch. Iron the seam allowances towards the top of the sleeve. On the allowance for the slot, iron the piping (3).

Remove the running threads from the slots. Perform a hem along the lower cut of the sleeve, while at the ends of the slots, process the corners with an “envelope”. At the top end of the vent, stitch the allowance under the vent to the top facing of the sleeve (4). Sew on the buttons, while grabbing the allowance under the slot.

IMPORTANT: if loops are provided on the sleeve, they are performed on the upper part of the sleeve before the allowance for the slot is sewn to the facing.

In this case, the facing of the sleeve should be wide enough so that it can be grabbed when sewing buttonholes. Stitches are sewn before sewing the lower sections of the sleeve (= elbow seam).

Sleeves are closed at the bottom. The upper part of the sleeve is cut along with the facing, the lower part of the sleeve is cut along with the allowance for the slot.

Baste the elbow sections of the sleeve, sweep the slot. Sew the seam of the sleeve from the top to the slot mark. Bartack at the beginning and end of the seam. Leave the slot sour cream for now.

Sew the top and side cuts of the allowance for the slot and facing. Cut the seam allowance of the lower part of the sleeve into the corner close to the stitching line (5). Iron the seam allowances from above to the notch, iron the slots allowance onto the upper part of the sleeve. Iron the seam allowances. Fold along the bottom of the sleeve.

Remove the running threads from the slots. At the bottom edge of the sleeve, sew the edges of the slots (6). Sew on the buttons, grabbing the seam allowance.

01:03 unknown 0 Comments

Hello fellow sewing lovers!

In this article, we will analyze the technology for processing shirt sleeves, as well as the technology for processing the cut of the fastener and the lower cut of the sleeve.

In previous articles, we found out that shirt-cut clothes differ in size and configuration of details: the armhole of the product is more deep and wide, and the sleeves have a small collar height and a minimum or zero fit. Therefore, the technology of connecting the sleeve with the product differs from technologies for sewing in a classic single-seam sleeve .

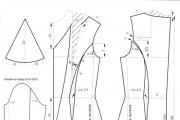

Cutting fabric. Prepare paper patterns shirt sleeve ,

And straps for processing the cut of the fastener .

Fold the fabric in two layers right side inward. We impose paper patterns of parts, observing the direction of the shared thread, which should run along all the parts, circle the patterns and add 1.5 cm to the allowances for all sections. We built the bar allowances directly on the paper pattern, so we simply circle this pattern.

We cut out the details from the fabric: we should get two details of the sleeve, cuffs - 2 pieces, strap - 2 pieces.

With threads of a contrasting color, we will transfer the control points to the second layer of fabric, or we will lay copy stitches.

On the details of the bar, we transfer the cut line and the fold line of the upper bar with copy stitches with contrasting threads.

We will strengthen the cut line on the front side with duplicating material. To do this, we will prepare two strips of interlining with a length equal to the length of the cut + 2 cm (12 + 2 \u003d 14 cm) and a width of 1.5-2 cm.

We duplicate the details of the bar if the fabric is thin, but not transparent, the bar from denser fabrics is not duplicated.

Let's draw a frame for the cut on the front side of the sleeve, the length of the frame is equal to the length of the cut + the allowance for the lower cut (12 + 1.5 = 13.5 cm), and the width is 1 cm.

Now we will transfer the frame lines and the cut line to the wrong side of the sleeve with copy stitches with threads of a contrasting color.

Let's put our bar with the front side to the wrong side of the sleeve, while the upper bar should be on the side of the front cut of the sleeve. We take the bar to the sleeve along the lines of the frame.

We sew the bar strictly along the lines of the frame. We sew from the side of the strap (the photo shows the side of the sleeve, so that it is more clear where the line should go).

We remove the basting and iron the seams on both sides.

Cut the sleeve along the cut line, not reaching the top line of the frame 1 cm. We will cut this section in both directions to the corners of the frame.

To make it easier to turn the bar to the front side, you can lay out the bar and the sleeve on the surface on opposite sides of the seam, iron the allowances on the side of the sleeve and on the wrong side of the sleeve, make a stitching around the frame, retreating 1 mm from the seam chip.

But you can not do this if the fabric is obedient enough.

Straightening the corners, turn the bar on the front side of the sleeve and iron the bottom bar

We turn off the allowance of the lower bar and sweep it to the wrong side and we outline the lower bar to the sleeve.

Let's stitch the bar with a bartack stitch, departing from the fold of the bar 1mm. Since we have a denim product, we will lay a line with a thread in a contrasting color.

Iron the seam on both sides.

Now fold the top bar with the front side inward along the fold line, equalize the cuts and grind the toe.

Be sure to iron the seam. We cut the allowances to 3-5mm and cut the allowance in the corner.

Turn the corner of the plank right side out and iron the fold line. Let's lay out the sleeve on the surface, equalize the sides of the cut and check the position of the top bar - it should completely cover the bottom bar.

We turn and sweep the allowance of the strap on the wrong side and we outline the bar to the sleeve along the side and top line (toe).

Let's stitch the upper bar with a thread of a contrasting color, retreating from the fold of the bar 1mm. Lay the line around the top bar. Then we lay out the sleeve on the surface, aligning the sides of the cut and stitch the upper bar along the horizontal line of the frame for the entire width of the bar. This way we hide the allowance of the bottom bar under the top bar.

Don't forget to iron the seams.

Connecting the sleeve to the product. Having processed the section of the fastener, we proceed to the processing of the sleeve itself. As I said above, the technology for joining a shirt sleeve is different from the processing of a classic set-in sleeve. First of all, the shirt sleeve is not sewn in, but stitched to the armhole of the product, while the product itself is connected only along the shoulder seams. After attaching the sleeve, the product is ground along the side cuts together with the side cuts of the sleeve with one seam.

The sleeves of the shirt cut are connected to the product with a sewing seam, while using third way making this seam. If the length of the eyelet is greater than the length of the armhole, then first you need to sutyuzhivat allowances of the upper sleeve so that the length of the eyelet becomes equal to the length of the armhole. According to the technology in shirt-cut products, the sleeve allowances are ironed towards the armhole, so we will turn the sleeve sleeve allowances to the front side by 7mm and sweep them.

We fold the sleeve part with the product with the front side inward and tuck the sleeve to the armhole (do not forget that the cut of the sleeve is on the side of the elbow cut, which means that we open the sleeves with a cut to the back of the product).

We sew the sleeve with a stitch with a bartack and iron the seam on the rib on both sides.

Now we will cut the armhole allowance to 5mm and iron the sleeve allowances to the armhole of the product.

On the front side of the product we will lay two finishing stitches contrasting thread from the side of the product. We will lay the first line, stepping back from the seam cleavage 1mm, and the second - parallel to the first at a distance of 7mm. We iron the seams and this is what we got.

We sew the product along the side cuts, at the same time grinding the side cuts of the sleeve, overcast the cuts and iron the allowances on the shelf.

You can connect the side sections of the product with a sewing seam, and stitch the sections of the sleeve, overcast and iron the allowances on the side of the shelf. Or completely connect the side sections of the product and the sleeves with a sewing seam, however, this method is rather difficult on the sleeve section, but if you wish, you can sew a sewing seam on the side sections of the sleeve. Choose the method that is most convenient for you, in my example the third method is shown.

We proceed to the processing of the lower cut of the sleeve.

Cuff processing. To prevent the cuffs from stretching during wearing, we will strengthen them with details from a duplicate material, cut to the size of the cuff without allowances.

We fold the cuff along the fold line with the front side inward, so that the allowances of one side are 2-3 mm larger, the smaller part of the cuff will be considered the top.

On the lower cut, the width of the sleeve is greater than the width of the cuff, it is necessary to measure these values, find the difference and remove this difference into a soft fold along the lower cut of the sleeve, stepping back from the upper bar 2 cm, while directing the fold towards the bar. A soft fold can be swept up or chipped off with a pin.

Fold the pieces right side together and tuck the top of the cuff to the bottom of the sleeve.

We grind the details, iron the seam on the rib on both sides and iron the allowances on the cuff.

We turn the cuff along the fold line to the wrong side, equalize the side sections and grind them. Be sure to iron the seams.

Cut off the allowances in the corners and turn the cuff right side out.

We turn the allowances of the lower part of the cuff to the wrong side and sweep them, and then we sweep the cuff itself, while the seam of attaching the upper part of the cuff will not be visible, since it is 2-3 mm smaller.

It remains for us to make a buttonhole on the cuff and sew on the button itself, but I will write about this in future articles. Now our sleeve looks like this.

For many needlewomen, it is not a problem to sew a knitted T-shirt or sweatpants. But when it comes to more complex work, for example, tailoring a shirt, you need to have either experience or a fairly good abstract with the theory of processing this product. Back yoke, shoulder seams, buttonholes and stand-up collar are usually easy to wear. But the processing of the cuff of the sleeve becomes a stumbling block for many.

The peculiarity of the long sleeve is that it has a slit, or, as it is also called, a slot. And if the short version is simply tucked up and adjusted, then the long version will need to be worked more carefully. There are several processing methods. They will be discussed further.

Varieties of processing

The cuff on the sleeves in a women's shirt can be decorated with a classic and fake vent, a cleanly turned cut, an air loop fastener and a zipper.

In a men's shirt, a classic slot is usually used. Only sometimes they make out a zipper and a purely machined cut. Even if the sleeve cuff is under for men, they make a slot and put a button in the middle of the cut.

Sleeve cut location

According to the cut, the long sleeve can be single-seam and double-seam. In both the first and second versions, an incision is made at the cuff. Everything is simple: the sections of the additional seam 10-12 cm from the bottom are left open. If the sleeve is one-sutural, it is folded along the sections. Next, the center of the lower cut is determined and the perpendicular is raised from it by 10-12 cm.

When sewing shirts with short sleeves, the cut is not made.

Option one: classic slot

We are used to the fact that in a classic shirt there are at least three buttons on the sleeve. Two on the cuff (to adjust its width) and one in the middle of a special cut. Such a clasp is usually made when processing a cut with a classic slot. In this case, the edges of the sleeve cuff coincide with the edges of the slots and form an overlap. The edge that is closer to the seam of the sleeve always serves as an allowance for the fastener. It is on it that the button is placed.

How to sew a cuff to a sleeve with a classic slot? First, two strips of fabric are cut out:

- twice as wide as the finished facing and 5 cm longer than the cut;

- 1.5 cm wide and 0.5 cm longer than the incision.

A large strip is used to decorate the outer edge of the cut, a smaller one is used to decorate the edge of the inner overlap.

When the incision is made, cuff parts already stabilized by interlining and interconnected are attached along the bottom. At the same time, the fabric of the sleeve is laid in folds, stepping back from the cut from the side of the part, the slots running along the top, 3-4 cm.

The slots of the left and right sleeves are processed in a mirror image.

Option two: overcut

One of the simplest options for processing a cut when sewing shirts is decoration. As a rule, with such processing, a button is not sewn in the center of the cut.

Option three: a clean cut

To decorate with this method, you will need a strip of fabric equal to the length of the sleeve cut plus 4 cm and a width of 4 cm.

This finishing option is most often used in women's shirts. Moreover, the length of the sleeve here can be any, and air loops from the braid can be inserted into the facing. With this type of incision processing, a regular inside-out lapel can be designed.

This method is also used when making a sleeve with a zipper. First, a zipper is attached, on top of it - a facing. Thus, a neatly designed lock comes out.

Option four: fake slot

The easiest and fastest way to create a sleeve vent is to make a fake vent. The length of the sleeve with this design can be any. As a rule, this method is used when sewing women's clothes. As a cuff, a strip of fabric is used, equal to the required length along the girth of the arm + overlap on the fastener. An incision is not made on the sleeve, and the fold is not closed into the cuff detail. The sleeve panel, which is not included in the cuff along the lower cut, is turned inside out twice and stitched, and a button is sewn on the cuff and a loop is sewn.

Option five: designing the cuffs of a two-seam sleeve

If, as planned, it should be with two seams, then the facings of the sleeve cut are made one-piece. This simplifies the processing a little, since you only need to properly lay and stitch the fabric.

Processing of the cut of the sleeve of the shirt. Now, for sure, the last one - the topic is fully disclosed, there are options for every taste.

So you can process not only the sleeve, but also the fastener on the polo shirt. In the latter case, the narrow facing should be replaced with a wide one.

Sleeve placket: fastener processing with two facings.

In the example, the layout for the right sleeve or for the “female” shirt fastener is considered. For the left sleeve or polo shirt for men, you need to “mirror” the curly facing.

First, draw a frame of the desired length and width. For the sleeve, the frame is approximately 1.5-2 cm wide and 10-15 cm long.

Two facings of the cut.

The first, - 2.5-3 cm wide, - is cut out along the shared thread or along the oblique, as desired. Length - 1 cm longer than the frame.

The second facing is figured with allowances of about 0.5 cm, “along the share”. Cut out as shown in the picture:

All details in the photo are located wrong side up. Now you need to attach both facings to the frame with allowances of 0.5 cm from the sides of the frame. Chip, carefully follow the borders of the frame. The rule here is: “the face of the facing + the wrong side of the sleeve.”

Stitch the facings along the long sides, strictly maintaining the points of the beginning of the lines in the corners of the frame.

Check the clarity of the shape of the frame on the front side

Cut the frame in the middle and at the corners of the frame, to the end points of the seam. The accuracy of the cut is the key to a clear shape of the future plank.

If necessary, trim the frame allowance for turning. In my example, such a need was for a narrow turning.

WTO! An iron in such operations is a sacred thing. However, as in all others, too.

Now we turn the whole structure over to the front side and continue to work with a narrow facing. Wrap the allowance, tuck the facing.

It is better to tack than to simply pin the folded edge with pins. So you will feel the lower border of the facing with your hands and fasten the layers securely and neatly. Stitch along the front side close to the tucked edge. Follow the boundaries of the frame. Remove basting threads.

Repeat the steps with curly facing. Wrap the second cut of the frame with curly facing. WTO. Tuck and bast a long cut, exactly aligning the trim with the sides of the frame with the bottom trim.

Turn the corner of the frame right side out. With a straight line along the short side of the frame, connect the corner and the tails of both facings.